- Rubber Synchronous Belt

- Double Side Synchronous Belt

- Rubber Open Timing Belt

- Multi-wedge Belt

- Plane Belt

- Special Belt

- Special Belt 2

- Automobile Timing Belt

- PU Synchronous Belt

- Synchronous Pulley

- Rock.Rock Lever

- Locking Assemblies And Cone Fastening

- Single Synchronous Belt

- Double Sided Timing Belt

- Thickened Single Tooth

- Special Single Tooth

- Open Tooth

- Multi Wedge Belt

- Timing Pulley Series

- Automotive Timing Belt

- PK Multi Wedge Belt

- Rubber V Tape

- Variable-Speed Belt

- Flat Belt

- Color PU Open And Timing Belt

- Lining For Cable Car

- Cutting V Tape

- Polyurethane Synchronous Belt

- Color Rubber Synchronous Belt

- TT5 Timing Belts

- Color PU Timing Belt

- Conjoined V Belt

The pitch and the tooth profile of the double toothed synchronous belt are equal to the tooth profile and pitch of the single tooth synchronous belt.

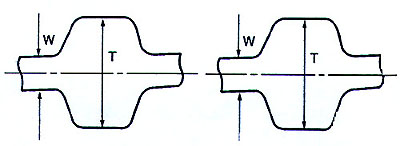

According to the arrangement of double tooth synchronous belt with teeth can be divided into two types: standard type DA double tooth synchronous belt, the two sides with teeth symmetrically arranged, see figure (a); DB type double tooth synchronous belt, the two toothed staggered arrangement, see figure (b)

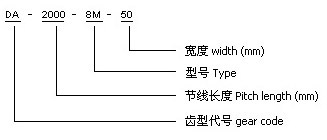

The specification, model and size of double tooth synchronous belt

| Model | W | T | Code | Section length | Tooth number |

| D-XL | 0.508 | 3.05 | 196XL-1970XL | 497.84-5003.8 | 98-985 |

| D-L | 0.762 | 4.58 | 203L-1988L | 514.35-5048.25 | 54-530 |

| D-H | 1.372 | 5.95 | 670H-2500H | 1701.8-6350 | 124-500 |

| D-XH | 2.794 | 15.49 | 700XH-2275XH | 1778.00-5778.5 | 80-260 |

| D-XXH | 3.048 | 22.11 | 700XXH-2625XXH | 1778.00-6667.5 | 56-210 |

| D-T2.5 | 0.60 | 2.00 | T2.5x500-T2.5x5000 | 500.00-5000.00 | 200-2000 |

| D-T5 | 1.00 | 3.40 | T5x500-T5x7000 | 500.00-7000.00 | 100-1400 |

| D-T10 | 2.00 | 7.00 | T10x500-T10x7050 | 500.00-7050.00 | 50-705 |

| D-T20 | 3.00 | 13.00 | T20x1700-T20x7000 | 1700.00-7000.00 | 85-350 |

| D-AT10 | 2.00 | 7.00 | AT10x500-AT10x7000 | 500.00-7000.00 | 50-700 |

| HTD.DA-3M | 0.760 | 3.10 | 501-3M-5010-3M | 501.00-5010.00 | 167-1670 |

| HTD.DA-5M | 1.143 | 5.26 | 500-5M-7000-5M | 500.00-7000.00 | 50-1400 |

| HTD.DA-8M | 1.372 | 8.17 | 512-8M-6880-8M | 512-6880 | 64-860 |

| HTD.DA-14M | 2.80 | 14.84 | 1750-14M-6860-14M | 1750-6860 | 125-490 |

| HTD.DA-S8M | 1.372 | 7.48 | S8M-512-S8M-6880 | 512-6880 | 64-860 |

Double toothed synchronous belt

Matters needing attention

1)Note that the product surface is clean, the belt should not be distorted, with teeth to be full.

2)Products in the transport, installation and other processes, no twists and turns, otherwise it will damage the skeleton material (glass fiber), the impact of the strength of the belt.

3)Products in the installation and use of the process, shall not scratch the belt, not with chemicals (especially strong oxidizing acid), try to avoid contact with oil and water for a long time, so as not to affect the life of the product.

4)When the product is replaced, the tension of the belt must be reduced to the minimum, so that it can be taken out. It is strictly prohibited to use the non professional tools to pry down under the condition of high tension.

Material selection and product characteristics

The belt body used Japanese imports of high-quality synthetic chloroprene rubber, and mixed with a variety of different uses of rubber materials; skeleton materials for high quality glass fiber cord imported from Japan; with tooth surface with high elastic nylon cloth 66 protection.

The pitch and tooth profile of the product are the same as those of single tooth.

The product is mainly used for double side transmission, with synchronous, simultaneous, double efficiency characteristics. A belt drive with the requirements and in the opposite direction, require special compact installation location, or in the main drive and auxiliary transmission linkage and other areas of high transmission requirements, reflects its excellence; product lightweight, non slip gear drive, low noise characteristics by the wide machinery, textile, precision instrumentation, petroleum chemical industry, communications cable industry awareness, has been widely recognized.